A bushing consists of two metal sleeves with different diameters arranged on the same axis, one inside the other, and separated by a layer of elastomer. This represents the standard bushing structure. In practice, while they share a general working principle, bushings can vary significantly from one another. Their design features are influenced by the structure of the component in which they are used and the expected loads. Differences can arise from factors such as the presence or absence of compensation (reverse) holes, the offset of metal sleeves, and whether they are subjected to torsional or stress work – all of which contribute to the variations in bushing design.

Regardless of their diverse shapes and sizes, all bushings share a common requirement for longevity: they must be monolithic. Simply placing an elastomer bushing between two metal sleeves can lead to rapid deterioration due to abrasion between the mating surfaces. The solution to this issue is straightforward: the inner elastomer bushing should be bonded to the metal sleeves. This condition is achieved by applying an adhesive layer that securely bonds the elastomer to the metal.

Bushings may contain elastomers with varying compositions, ranging from traditional rubber to polyurethane. In recent years, polyurethane bushings have gained popularity. Synthetic polymers like polyurethane effectively compete with rubber in terms of vibration dampening quality.

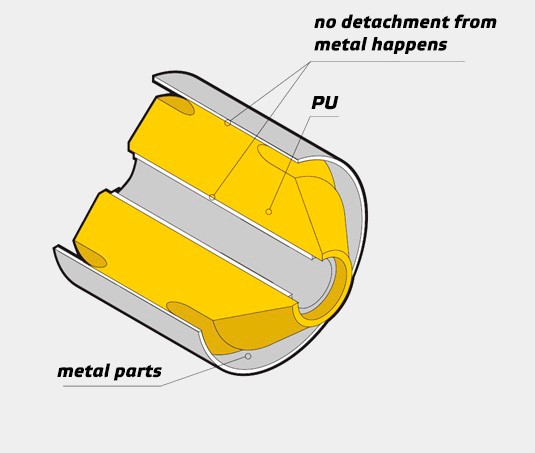

The adhesion of polyurethane (PU) to metal parts is typically stronger than that of rubber, unless otherwise specified. It ensures that detachment from the metal does not occur.