This operation is straightforward for those with the necessary tools and expertise.

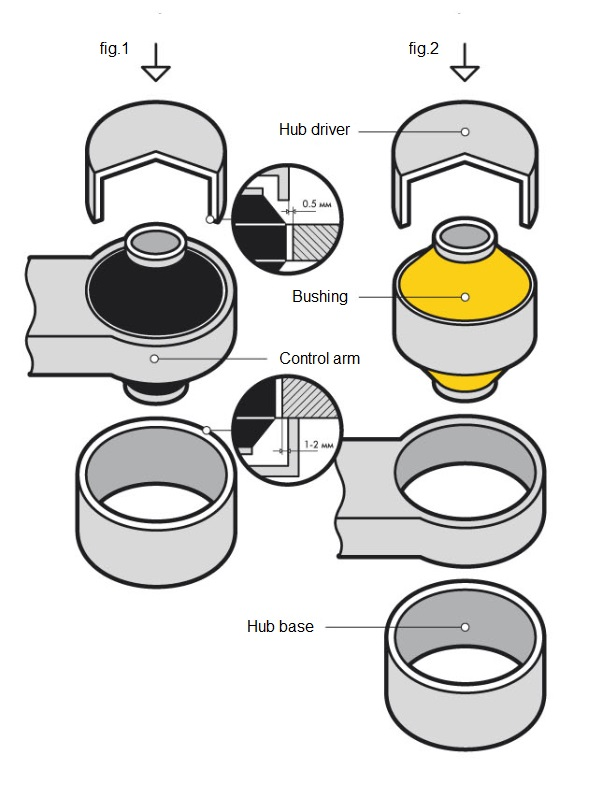

Before starting the work, pay close attention to the placement of replacement parts within the housing bore. Factors like the positioning of the bushing, the depth of pressing, and other details are crucial for the proper functioning of the suspension. To ensure correct installation, mark both the arm and the old part to indicate the precise location of the bushing. Before fitting the new part, mark it in the same manner as the old one.

Select an appropriate hub driver and hub base for removing and installing the part. Ensure that the dimensions of the hub base do not obstruct the removal of the bushing from the housing bore. Additionally, the dimensions of the hub driver should not cause deformation of the outer metal shell of the bushing or the housing bore. For bushings without an outer metal shell, use a taper to apply the necessary pressure to the inner metal sleeve. In the case of a U-shaped arm, opt for a strut and follow the specified direction for removing and installing the part. When dealing with bushings without an outer metal shell, apply a consistent amount of grease to the part.

After removing the part, thoroughly clean the housing bore and assess it for any damage or wear. Replace any suspension components that display signs of abrasive or corrosive wear.

Compare the diameters of the housing bore and the outer metal shell of the new bushing. The diameter of the outer metal shell should exceed that of the housing bore by 0.2-0.5 mm to ensure proper attachment of the bushing within the housing bore. If there is no difference in diameter, double-check the bushing selection or consider replacing the arm.

These are the fundamental principles for the removal and installation of bushings. If you have any doubts about successfully replacing the bushings, it’s advisable to seek assistance from a professional service station.

Always read the provided instructions before installation! Detailed instructions are included with the parts and can also be found on our website.