Bushings in a car’s suspension serve multiple essential purposes. They are designed to isolate the vehicle’s body from the noise and vibrations generated while driving. Additionally, they play a crucial role in protecting suspension components from wear at their mounting points, ensuring their stable positioning and reliable connection to the car’s body. The variety of bushing shapes available depends on the specific design characteristics of each car brand.

In contrast to bushings, regular bushings are not reinforced with metal elements. This lack of reinforcement significantly shortens their service life, rendering them expendable.

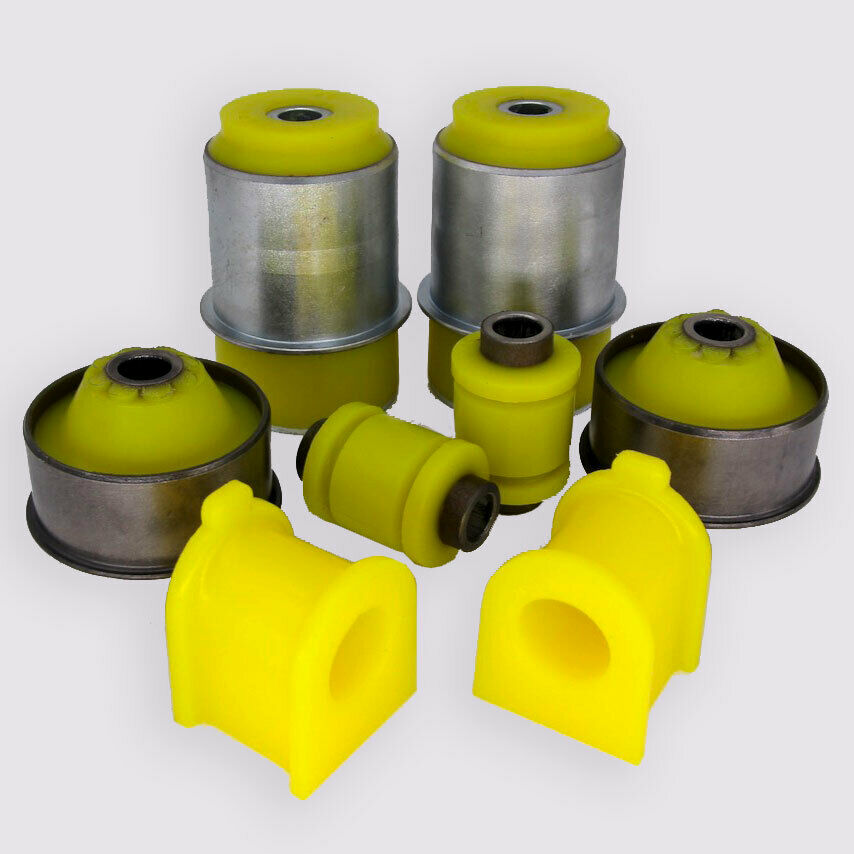

Stabilizer bar (or anti-roll bar) bushings bear substantial loads during cornering and when navigating potholes. The wear and tear of stabilizer bushings can be identified through visual inspection. Signs of deterioration include abrasions, cracks, and gaps between the bushings and the stabilizer, indicating the need for replacement. Dirt and moisture can infiltrate the clearance between the bushing and the stabilizer, accelerating wear and potential damage to the stabilizer itself. Radial displacement of the stabilizer within worn-out bushings can lead to suspension knocks.

Other suspension components, such as shock absorbers, anti-roll bar links, leaf springs, and rods, may also be connected to the vehicle body using bushings. These bushings are subject to similar types of damage, often accompanied by creaking and knocking noises within the car’s suspension.

When replacing bushings, it is crucial to thoroughly clean the housing surfaces, removing rust, dirt, and remnants of old bushings. All worn-out fasteners should be replaced, and new bushings should be adequately lubricated before installation. These steps help extend the lifespan of the bushings and other suspension components.