Automotive suspension is designed for the elastic connection between the wheels and the vehicle body, as well as for dampening vibrations caused by road irregularities. The suspension system aims to provide comfortable driving with a smooth ride, ensure traffic safety, and maintain cornering stability. The characteristics of a suspension system depend on various factors, including the parameters and interactions of individual components, the type and stiffness of elastic elements, stabilizers, arms, dampers, engine mounts, wheelbase, track width, and, notably, the type of tires used.

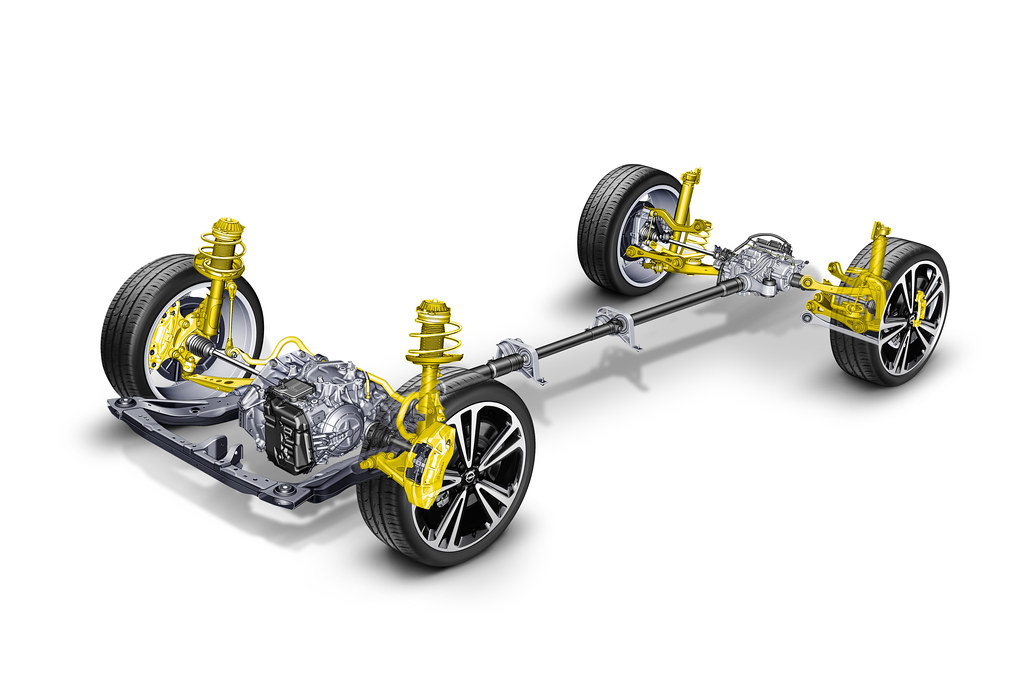

A car’s suspension system comprises guiding and elastic elements, damping elements (shock absorbers), anti-roll bars, wheel supports, and securing components.

Guiding elements establish the intended path of the wheels in relation to the vehicle body. Various arms and rods, such as control and tracking arms, are used as guiding elements.

Elastic elements absorb and transmit reaction forces to the vehicle body when the wheels encounter road bumps. Rubber, pneumatic, or steel elastic elements are employed in suspensions. Steel elastic elements include springs, leaf springs, and torsion bars.

Rubber bushings and bushing pads help reduce suspension energy. Rubber elastic elements primarily serve to isolate the body from the noise and vibrations generated during driving, while also providing a connection between suspension components and the car body and wheel supports.

Shock absorbers are designed to dampen vibrations of the vehicle body resulting from road irregularities.

The anti-roll bar, also known as the sway bar or stabilizer bar, is a rod with a circular cross-section. It is attached to the body and connects the arms of opposite wheels on the same axle. The stabilizer bar reduces body roll and enhances vehicle stability during cornering. It can be installed on both the front and rear axles.

Suspension systems are generally categorized into two fundamentally different types: dependent and independent.

In a dependent suspension, the wheels of one axle are rigidly connected to each other, and the movement of one wheel on the axle affects the other. Dependent suspensions have seen continuous improvement and are still used in various forms. This type of suspension offers several advantages, such as maintaining a constant wheel track; the wheels always remain parallel to each other. Even in the absence of a drive axle, rear wheels may experience slight misalignment, but on relatively flat surfaces, they remain optimally perpendicular to the road surface, regardless of suspension travel and body roll. Dependent suspensions are highly reliable due to their simplicity.

Independent suspension, on the other hand, does not have a rigid connection between the wheels on an axle. Thus, the movement of one wheel has little effect on the other. Additionally, the alignment and, in some cases, the wheelbase may change significantly during compression and rebound of the suspension. Independent suspension designs reduce unsprung weight and improve ride comfort. In modern cars, independent suspension is the standard design for both front and rear suspensions.